In home textile design, printing patterns and repeat sizes are core elements that influence the product's appearance and production process. According to standard dyeing factory specifications, repeat sizes are divided into 32cm, 64cm, and 96cm for rotary screen printing, while flat screen printing is not limited by these sizes. Additionally, the choice of printing process significantly affects the fabric's hand feel; for example, polyester fabrics can use pigment printing or disperse printing, while cotton fabrics can use reactive printing or pigment printing. This article will delve into the role of these parameters in home textile design and their impact on the final product.

1. Diversity of Printing Patterns

Printing patterns are the visual focus of home textile products, with common types including:

- Floral patterns: Classic and popular, suitable for bedding and curtains, creating a warm atmosphere.

- Geometric patterns: Presented in forms like stripes and checks, with a strong modern feel, suitable for tablecloths and decorative fabrics.

- Abstract patterns: Free and unrestrained designs that attract young consumers, often used in personalized home textile products.

Each pattern type has its unique market positioning and application scenarios, and designers need to choose based on the needs of the target customers.

2. The Importance of Repeat Sizes

Repeat size refers to the length at which the printed pattern repeats on the fabric, directly affecting the design effect and production efficiency.

2.1 Repeat Specifications for Rotary Screen Printing

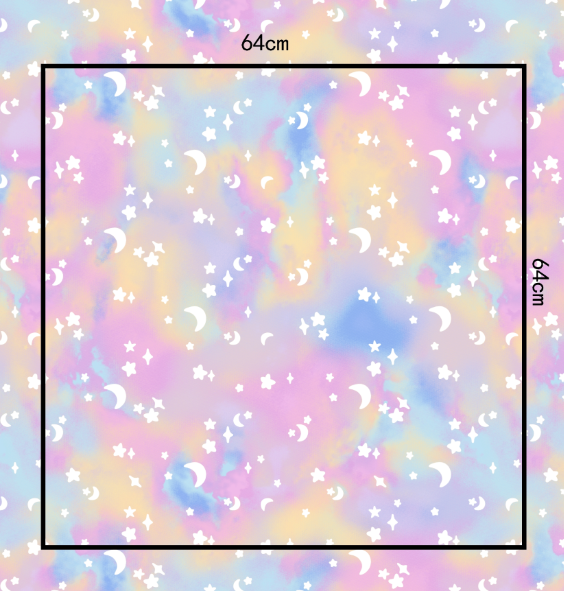

The circumference of the screen cylinder in rotary screen printing machines determines the repeat size, with standard specifications being:

- 32cm: Suitable for small, dense patterns such as small florals or miniature geometric designs.

- 64cm: Medium repeat, balancing detail and visual impact, commonly used for bedding sets.

- 96cm: Large repeat, suitable for large floral or landscape patterns, applicable to decorative fabrics.

These fixed sizes require designers to ensure seamless pattern continuity while optimizing production efficiency.

2.2 Flexibility of Flat Screen Printing

Flat screen printing is not limited by the above sizes, and the repeat length can be freely adjusted according to design needs. This process is suitable for small batch or high-end custom products but has higher production costs and lower efficiency.

2.3 Application Considerations for Repeat Sizes

- Small repeat (32cm): High production efficiency, low cost, suitable for the mass market.

- Large repeat (96cm): Strong visual impact, suitable for high-end or personalized designs but requires more precise equipment support.

3. Printing Processes and Fabric Hand Feel

Different printing processes not only affect the pattern effect but also directly determine the fabric's hand feel. Below are common fabric and process combinations:

3.1 Polyester Fabrics

- Pigment printing: Pigments adhere to the fabric surface, with a simple process and low cost, but the hand feel is relatively stiff, suitable for decorative products.

- Disperse printing: Dyes penetrate into the fiber, resulting in a soft hand feel and good durability, suitable for bedding and curtains.

3.2 Cotton Fabrics

- Reactive printing: Dyes chemically react with cotton fibers, producing vibrant colors, a soft hand feel, and good breathability, suitable for high-end home textiles.

- Pigment printing: Stiffer hand feel, low cost, suitable for budget-limited decorative fabrics.

3.3 Impact of Processes on Hand Feel

- Softness: Disperse printing and reactive printing maintain the fabric's softness, suitable for close-to-skin use.

- Durability: Reactive printing has high color fastness, suitable for products that are frequently washed.

- Cost: Pigment printing is economical, while disperse and reactive printing are more suitable for mid-to-high-end markets.

4. Balancing Design and Production

In practical applications, designers need to comprehensively consider patterns, repeat sizes, and printing processes:

- Market positioning: Small repeats and pigment printing are suitable for the mass market, while large repeats and reactive printing are more suitable for high-end customers.

- Functional requirements: Bed sheets need to be soft and durable, while curtains emphasize decorativeness.

- Production efficiency: Rotary screen printing is suitable for large-scale production, while flat screen printing is more flexible but has higher costs.

5. Conclusion

Home textile printing design is a discipline that combines art and technology. Repeat sizes (32cm, 64cm, 96cm for rotary screen printing and the flexibility of flat screen printing) and printing processes (pigment/disperse printing for polyester fabrics, reactive/pigment printing for cotton fabrics) together shape the product's appearance and hand feel. By rationally selecting these parameters, designers and manufacturers can meet the needs of different markets and create home textile products that are both beautiful and practical.