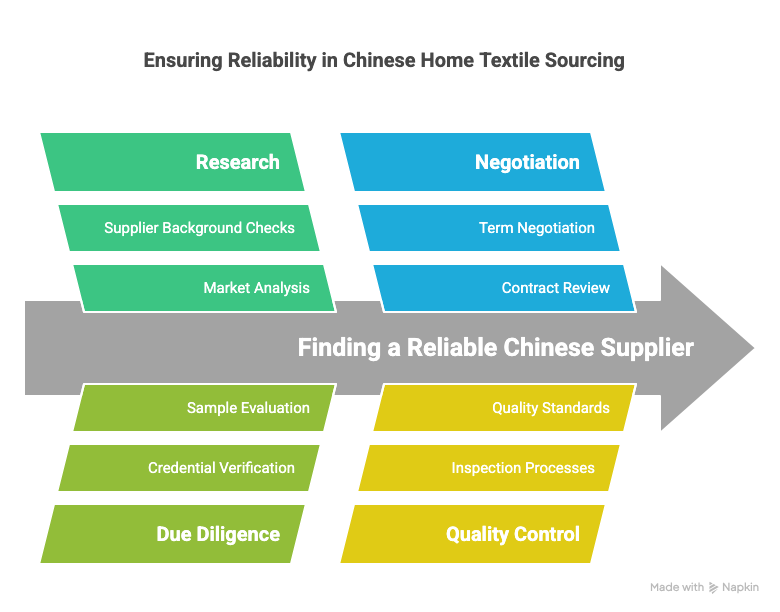

Struggling to find a reliable supplier? Big retailers demand perfection, and a bad choice can sink your project. I'll show you how the best Chinese factories consistently deliver.

Chinese bed linen factories meet global demands by securing key certifications, having massive production capacity to ensure on-time delivery, and implementing rigorous, multi-layered quality control systems that align with the high standards of retailers like Target and Costco. This ensures consistency and consumer satisfaction.

So, you see the big picture. But what really separates a good factory from a great one? It is more than just ticking boxes. It is about building a partnership. I have seen this firsthand in my years in manufacturing, both in molds and other products. Let's dig into the details of what makes these partnerships work. We will explore how these factories have become so essential to the global home goods supply chain.

What Makes a Chinese Bed Linen Supplier a Key Partner for Top US Brands?

Choosing a supplier feels like a gamble. You need a partner, not just a factory. A wrong choice can lead to costly mistakes and a damaged brand reputation.

A key partner goes beyond production. They have North American-recognized certifications like OEKO-TEX or BSCI, dedicated English-speaking teams, and a deep understanding of the retailer's brand standards. This proactive approach builds trust and ensures a smooth, long-term relationship.

When big retailers like Target look for a supplier, they are not just buying a product. They are buying a promise of reliability and safety. The first thing they look for is proof of a quality system. This is where certifications come in. They are the ticket to the game. Without them, a factory’s door is closed to these retail giants. I remember a client in my early days in the plastics business. He chose the cheapest factory for a new product, ignoring my advice to check for ISO certification. The first shipment was a disaster, full of defects. It cost him his contract. The same rule applies to textiles. Certifications are your first line of defense. They show that a factory has invested in its processes and is serious about quality.

| Certification | What it Guarantees | Why it Matters to Target/Costco |

|---|---|---|

| OEKO-TEX STANDARD 100 | Textiles are tested and free from harmful substances. | Protects consumer health and the retailer's brand image. |

| BSCI (Business Social Compliance Initiative) | The factory meets ethical and social standards. | Ensures corporate social responsibility and avoids bad press. |

| ISO 9001 | A strong quality management system is in place. | Guarantees consistent product quality and process control. |

Beyond Price: What Quality Controls Define the Best Bed Linen from Chinese Manufacturers?

Worried about quality fading after the first wash? Inconsistent quality can destroy customer trust. You need to know what to look for beyond the beautiful initial sample you received.

The best manufacturers use a multi-stage quality control process. This includes raw material inspection, in-line production checks, and final random inspections based on AQL standards. They test for colorfastness, shrinkage, and seam strength to ensure every item meets strict specifications.

A factory that works with a major retailer has a quality system that is woven into every step of production. It is not just a final check. It is a continuous process. I have walked through dozens of factories in China, and the best ones operate like a well-oiled machine. It starts the moment the raw materials arrive.

- Raw Material Inspection (IQC): Before a single thread is cut, teams inspect the rolls of fabric. They check for the correct thread count, color consistency against a master sample, and any weaving defects. A small flaw in the fabric can ruin a whole batch of sheets.

- In-Process Quality Control (IPQC): As the sheets are being cut and sewn, supervisors and dedicated QC staff patrol the production lines. They check for straight seams, correct stitch density, and proper dimensions. This prevents thousands of faulty items from being made.

- Final Quality Control (FQC): This is the final gate. Before the products are packed, a separate QC team performs a random inspection based on an AQL (Acceptable Quality Limit) standard. They might pull 200 units from an order of 10,000 and check them for any defect. If they find too many problems, the entire batch is rejected.

Are Supply Chain Innovations from China's Home Textile Sector Reshaping Global Bed Linen Sourcing?

Afraid of your supply chain breaking? Global disruptions are common. An inflexible supply chain can mean empty shelves and lost sales, which is a retailer's worst nightmare.

Yes, they are. Chinese factories are adopting smart manufacturing and data integration. They use ERP systems to track orders, manage inventory, and optimize production schedules in real-time. This creates a more transparent, resilient, and efficient supply chain for global retailers.

The image of a Chinese factory as just a place with rows of sewing machines is outdated. The top-tier factories I've worked with are technology companies as much as manufacturers. In my field of CNC machining, we rely on software to control every micron of movement. The textile industry is no different. They are using technology to manage the flow of information and materials. The core of this is the ERP (Enterprise Resource Planning) system. Think of it as the factory's central brain. It connects the sales order from Costco directly to raw material purchasing, production scheduling, and shipping logistics. This gives the retailer clear visibility into where their order is at all times. They also use automation, like computer-guided fabric cutters that work with incredible speed and precision, reducing waste. This move towards a data-driven approach means they are not just reacting to orders. They are predicting problems and optimizing the entire process.

From Factory Floor to Retail Shelf: How Do Chinese Bed Linen Exporters Ensure On-Time Delivery for Major Retailers?

Late shipments can cause huge penalties from retailers. This pressure is intense. One delay can ruin a partnership and cost you dearly in fees and lost trust.

They ensure on-time delivery through massive production capacity and meticulous planning. Factories reserve production lines for major clients, pre-book shipping containers months in advance, and have dedicated logistics teams to manage documentation and customs clearance seamlessly.

Meeting the delivery deadlines for a retailer like Costco is non-negotiable. They have chargebacks for late shipments that can wipe out a supplier's profit. So, these factories do not leave it to chance. The first key is sheer scale. The factories that supply these giants are not small workshops; they are enormous campuses. I like to use a highway analogy. A small factory is a single-lane road that gets jammed easily. These large factories are like 8-lane superhighways. They can handle a huge volume of orders without slowing down. For a big order, they will block out entire production lines for weeks or months, guaranteeing the capacity is there. The second key is logistics mastery. The job is not done when the sheets are sewn. They have expert logistics teams that handle the complex process of getting goods across the ocean. They book space on container ships far in advance, especially before busy seasons. They prepare all the export and import documents perfectly, because one small error can cause a shipment to be stuck in customs for days. It is a complete, end-to-end system designed for one purpose: on-time delivery.

Conclusion

Choosing the right Chinese supplier involves checking for certifications, deep quality control, modern supply chains, and massive capacity. This total approach ensures your products meet global retail standards.